No.159,Taixin road,Ningxi town,Zengcheng districtGuangzhou, China

+86-13822298758/13922700490Free time

Monday - Saturday Sunday CLOSEDit's all about integrity!

No.159,Taixin road,Ningxi town,Zengcheng districtGuangzhou, China

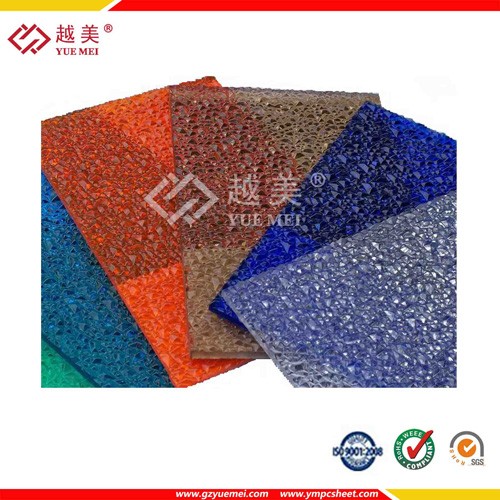

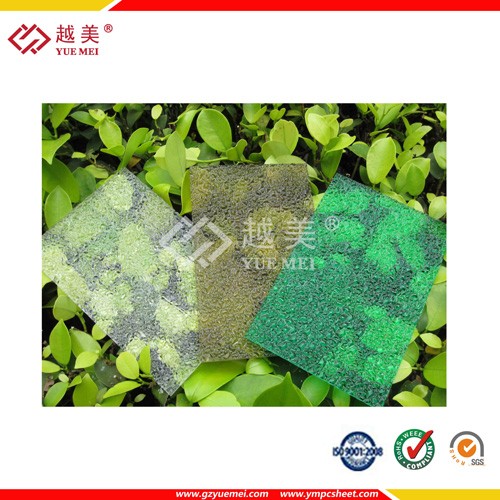

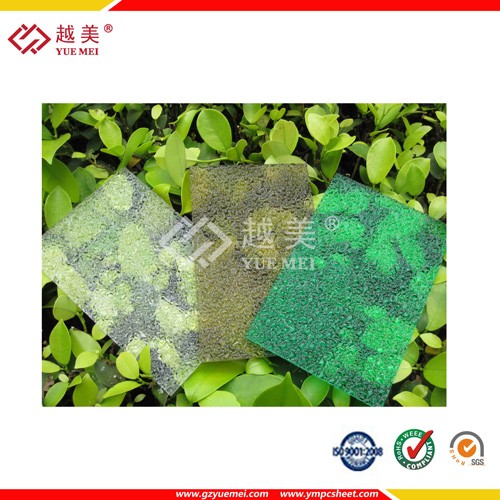

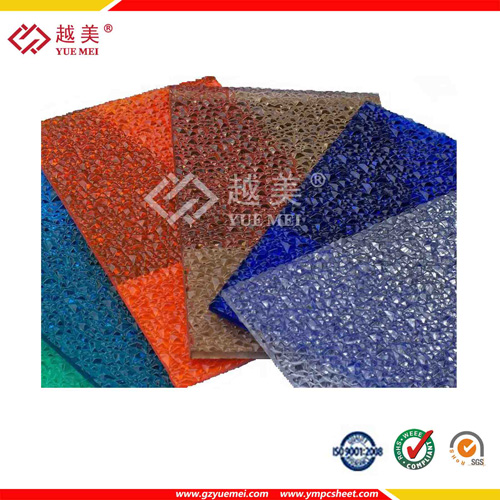

Colorful Polycarbonate diamond embossed sheet

Surface of Polycarbonate embossed sheet enhance the toughness, and it also reflect glare which is direct irradiation on the sheet, disperse reflected light, and reduce light pollution.

Surface looks graceful appearance and it can resist scratching. It is particularly suitable for various kinds of designs.

DESCRIPTION

1.Excellent impact resistance: 250~300 times that of same thickness glass, 30 times that of acrylic sheeting, 2 times of the toughened glass. Almost no risk of fracture, has the reputation of “bullet-proof glass,”

2.transmission of light: excellent lighting,its transparency is comparable with the glass. The UV coatings stop the sunlight making the sheet becoming ,yellowing, atomization,poor translucent.

3.weather resistance:It has UV Coating on the surface of sheet, and prevent the sheet becoming yellow under the sunshine.

4.Flame resistance: The polycarbonate panels itself is not spontaneous combustion, and has selfquenching. In line with the EU ROHS Directive and strict UL safety specifications, UL94 V0 fire rating level, V2, HB. PC board ignition point is 630 degrees Celsius, away from the fire self-extinguishing, does not produce toxic gases when burned, will not contribute to the spread of fire

5.Heat resistance, cold resistance: in Celsius -40 ℃ to +120 ° C temperature range without causing the deformation quality deterioration. PC board does not occur in the -100 ℃ cold brittle, does not soften at 135 ℃ were no significant changes in the harsh environment, such as mechanical properties.

6.Light weight: only 1/12 of the weight of glass of the same thickness. It can be easily cold bent as well as thermal shaping

7.Sound insulation: PC board has good sound insulation, better sound insulation than the same thickness of glass and acrylic plate, under the conditions of the same thickness, the PC board insulation is more improve 3-4DB than glass. it is the material of choice for highway noise barriers In the international arena

Item | Standard Width (mm) | Thickness(mm) | Weight(kg/ m2) | Min Curving Radius(mm) | Min Span Accordingly (mm) | General Color |

Polycarbonate Diamond Embossed Sheet | 1220 1560 1820 2100 | 2.4 | 2.88 | 430 | 860 | Clear Blue Green Opal Bronze Orange Yellow |

3.0 | 3.6 | 540 | 1080 | |||

3.8 | 4.56 | 680 | 1360 | |||

4.0 | 4.8 | 720 | 1440 | |||

5.0 | 6.0 | 900 | 1800 | |||

6.0 | 7.2 | 1080 | 2160 |

Remark: 2.4mm-3.0mm, 30m length can be in roll. 3.6mm-4.5mm,18m length can be in roll.5mm or above, packed as sheet.

Note: Special colors and specifications can be customized.

1, building materials: polycarbonate sheet have good transparency, impact resistance, anti-UV and its dimensional stability and good molding properties, it’s much better than traditional CONSTRUCTION like inorganic glass in significant performance advantages.

2, automotive industry: Polycarbonate has good anti-impact, anti-heat distortion performance, and good weather fastness, high hardness, it is applied to various parts of the production of cars and light trucks, which are mainly concentrated in the lighting system, dashboard, heating plate, defroster and polycarbonate alloy bumper.

3, production of medical devices: polycarbonate article can be subjected to steam , heating and a large dose of radiation sterilization and not turn yellow and physical degradation occurs, which is widely applied to the artificial kidney hemodialysis equipment and other needs operating under transparent, intuitive conditions to be repeatedly sterilized medical equipment. Such as the production of high-pressure syringe, surgical masks, disposable dental appliances, blood separator

4 aviation and aerospace fields: In recent years, with the rapid development of aviation and aerospace technology, according to statistics, only Boeing aircraft with polycarbonate components amounted to 2500, and polycarbonate stand-alone consumes about 2 tons. Spaceship using hundreds of different configurations by glass fiber reinforced polycarbonate parts and astronaut’s protective equipment

5 packaging: polycarbonate products with light weight, impact resistance and transparency, no deformation and maintain the advantages of transparent treatment with hot water and caustic solution and dried, some areas of PC had completely replaced the glass bottles.

6,electrical and electronic fields: having a good and constant electrical insulating properties of polycarbonate within a wide temperature and humidity range, is an excellent insulating material. Good flame resistance and dimensional stability so that it formed in the electrical and electronic industry, the polycarbonate sheet application areas is mainly used for the production of a variety of food processing machinery, power tool housings, body, bracket, freezer drawer and vacuum cleaner parts, etc.. Important components for higher accuracy requirements of parts of computers, video recorders and color TV, polycarbonate material shows a very high value in use.